Our concurrent engineering and mold fabrication services at Reliable Formed Plastics, LLC support customers from initial concept through full production. Whether customers have a complete CAD model, or simply an idea, we offer the services they need to make their project a reality. Unlike many thermoforming facilities, everything we do is completely custom. Non-Disclosure Agreements (NDA) can be provided at no additional charge. All customer plans are verified for manufacturability, and any necessary modifications can be made as needed. Material selection is an important aspect of the development process. With a wide range of thermoplastics available, engineers can assist customers in choosing the ideal option to meet their performance and cost requirements. Request for Quote today!

Our concurrent engineering and mold fabrication services at Reliable Formed Plastics, LLC support customers from initial concept through full production. Whether customers have a complete CAD model, or simply an idea, we offer the services they need to make their project a reality. Unlike many thermoforming facilities, everything we do is completely custom. Non-Disclosure Agreements (NDA) can be provided at no additional charge. All customer plans are verified for manufacturability, and any necessary modifications can be made as needed. Material selection is an important aspect of the development process. With a wide range of thermoplastics available, engineers can assist customers in choosing the ideal option to meet their performance and cost requirements. Request for Quote today!

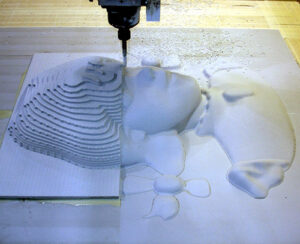

Once the plan has been finalized, a prototype mold is created. Prototype molds can often be milled from medium density fiberboard. MDF is a very cost effective material for producing prototype or very low volume vacuum forming molds and can be machined quickly. Prototype parts are provided to the customer for final approval before full production molds are fabricated. Our production molds can be constructed of various materials (i.e. epoxy, fiberglass, aluminum) suitable for multiple vacuum forming cycles and is capable of capturing fine part details. Depending on production volume, multiple molds can be made to expedite production. In addition to concurrent engineering and mold fabrication, we provide CNC routing, heat bending, assembly, and packaging services. Because all of these services are performed in-house, lead times are very competitive. For more information about our services, see the table below, or contact us directly!

Once the plan has been finalized, a prototype mold is created. Prototype molds can often be milled from medium density fiberboard. MDF is a very cost effective material for producing prototype or very low volume vacuum forming molds and can be machined quickly. Prototype parts are provided to the customer for final approval before full production molds are fabricated. Our production molds can be constructed of various materials (i.e. epoxy, fiberglass, aluminum) suitable for multiple vacuum forming cycles and is capable of capturing fine part details. Depending on production volume, multiple molds can be made to expedite production. In addition to concurrent engineering and mold fabrication, we provide CNC routing, heat bending, assembly, and packaging services. Because all of these services are performed in-house, lead times are very competitive. For more information about our services, see the table below, or contact us directly!

Capabilities

Mold Composition

Production Molds

Concurrent Engineering for Manufacturing

Mold Materials

- MDF (Prototype Molds)

- Epoxy Board (Production Molds)

- Fiberglass

- Aluminum

Molding Processes

- Vacuum Forming

- Drape Forming