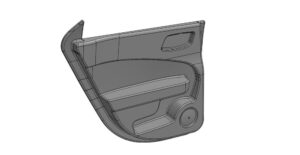

At Reliable Formed Plastics, our precise focus on concurrent engineering makes our company a dependable partner. We have more than 30 years of experience serving a diverse range of industries and have proven qualifications in industrial concurrent engineering and thermoforming technology.Through collaborative consultation, we can help transform your ideas into working concepts and provide 3D visual renderings for your approval. We use the latest versions of advanced solid modeling software to create CAD models that we encourage you to view from every perspective for validation. From these we can create vacuum formed prototypes for proof-of-concept and functionality studies. As masters of the heavy gauge thermoforming process, we have deep insight into the distinct molding characteristics of each plastic material, and can guide you through the selection process. In addition to building, we can also help engineer a productive framework for inspection, assembly, packaging, and shipping of your product. Request for Quote today!

Our vision is to support our customers by developing fresh ideas for delivering practical and cost effective solutions to any concurrent engineering challenge. After prototype development, we can easily transition to production tooling and ramp up to full capacity. For more information about our concurrent engineering capabilities, see the table below, and we would welcome the opportunity to consult on your next development project

Our vision is to support our customers by developing fresh ideas for delivering practical and cost effective solutions to any concurrent engineering challenge. After prototype development, we can easily transition to production tooling and ramp up to full capacity. For more information about our concurrent engineering capabilities, see the table below, and we would welcome the opportunity to consult on your next development projectCapabilities

Consulting

3D Modeling

Prototyping

Rapid Prototyping

QC

Engineering

Concurrent Engineering and Development – (CAD and CAM)

Reverse Engineering

Materials

ULTEM (PEI)

Polyethylene

Polypropylene

Boltaron

HDPE

Nylon

PEEK

PETG

Polycarbonate (Lexan) (FR)

Acrylic (Plexiglas)

Styrene

Polyphenylene Sulfide (PPS)

Composite/Fiber Impregnated Material

Acrylic-Polyvinyl Chloride (Kydex)

MasterCAM (MDX, MC8, MC9, SET)

Additional Thermoplastic Materials

File Formats

- MasterCAM (MDX, MC8, MC9, SET)

- SolidWorks (SLDPRT, SLDDRW, SLDDRT)

- Initial Graphics Exchange Specification, ANSI file format.

- Standard for the Exchange of Product Model Data

- AutoCAD (DWG, DWZ)

- Pro-E or Pro/Engineer (DRW, PRT, XPR)

- SolidEdge (DFT)

- Drawing Interchange Format, or Drawing Exchange Format

- Most Major CAD Formats Can be Accepted

- AutoDesk Inventor

- IGES/IGS

- STEP/STP

- ParaSolid

- EPS

- DXF