Thermoforming Plastic Experts for Custom, Heavy-Gauge Parts

Precision, Quality, and Rapid Turnaround — Serving the Southeast and Beyond

Why Choose Reliable Formed Plastics?

Heavy-Gauge Expertise:

Vacuum thermoforming of thick sheets up to 0.25″, with draw depths of 2–3 feet.

Large-Scale Capability:

Form sizes up to 6′ × 12′ for panels, enclosures, trays, canopies, and more.

Certified Quality:

AS9100 & ISO 9001 certified — trusted by aerospace, medical, automotive, and more.

Fast Quotes, Responsive Service:

Typical quotes delivered within 48 hours when technical details are provided.

Turnkey Solutions:

From CAD design to mold development, forming, trimming, and value-added assembly.

Vacuum Thermoforming Capabilities

Large Part Vacuum Forming

- Ideal for panels, enclosures, medical device housings, agricultural canopies, and more.

- Tolerances to ±0.010″ for precise, repeatable quality.

Prototyping & Low-Volume Production to Inventory Management & On-Demand Services

- Support for entrepreneurs, engineers, and product developers — from one-off prototypes to production runs.

Assembly & Value-Added Services

- Mechanical fastening, chemical welding, rivet installation, foam filling, and other assembly solutions.

- Add value and simplify your supply chain.

Industries Served

Aerospace & Defense (AS9100 certified)

Medical Device Components

Automotive Panels & Trays

Agricultural

Equipment

Material Handling Solutions

Materials We Work With

ABS:

Versatile and cost-effective for industrial use.

HDPE:

Tough, chemical-resistant

options.

Kydex & Boltaron:

For high-spec applications like medical and aerospace.

Take one thing off your plate, Count on Reliable for Quality, On-budget Thermoforming, right when you need it.

Design & Engineering

Share your CAD file or concept—we'll work with you to refine the design for manufacturability and cost-efficiency.

Tooling & Forming

We develop custom molds and thermoform your parts with precision and consistency.

Finishing & Quality Assurance

CNC trimming, assembly, and AS9100-certified inspections ensure every part meets your exact standards before packaging.

CNC Trimming & Assembly

5-axis CNC routers ensure exacting final part dimensions.

Final QA & Packaging

AS9100-certified inspections for quality and compliance.

Get Your Project Started Today

What Makes Us Different

AS9100 & ISO 9001 Certified:

Meets aerospace and defense requirements — ensuring reliable, repeatable quality.

Responsive Quotes (48 hours):

Once technical details are provided, expect a prompt and accurate quote.

Heavy-Gauge & Custom Expertise:

Serving complex and large parts with an emphasis on high-tolerance production.

Turnkey Solutions:

From CAD to finished part — one trusted partner for your vacuum thermoforming needs.

Strategic Southeast Location:

Lower shipping costs and faster service for customers throughout Alabama, Tennessee, Georgia, Florida, South Carolina, Louisiana, and beyond.

Thermoforming Plastics Process

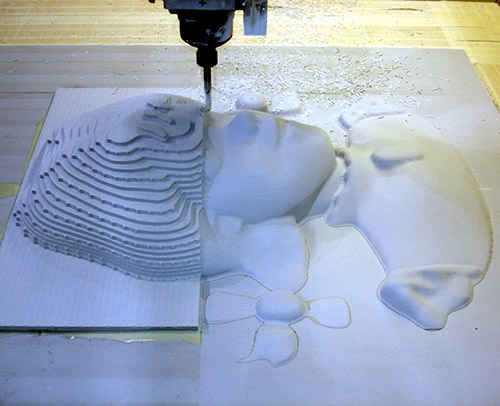

1. Design & Engineering

Collaborative DFM Review

We work side‑by‑side with your design team to optimize wall thickness, draft angles, and rib placement—catching potential issues before tooling begins.

Our engineers work side‑by‑side with your design team to optimize wall thickness, draft angles, and rib placement—catching potential issues before tooling begins.

Prototype & Fit‑Check Samples

Produce small‑scale mock‑ups or 3D‑printed prototypes to validate form, fit, and function. Early feedback loops help reduce iterations later.

Produce small‑scale mock‑ups or 3D‑printed prototypes to validate form, fit, and function. Early feedback loops reduce costly iterations later.

DFM Report

You receive a detailed Design‑for‑Manufacturing report outlining material recommendations, potential cost drivers, and risk mitigation strategies.

Receive a detailed Design‑for‑Manufacturing report that outlines material recommendations, potential cost drivers, and risk mitigation strategies.

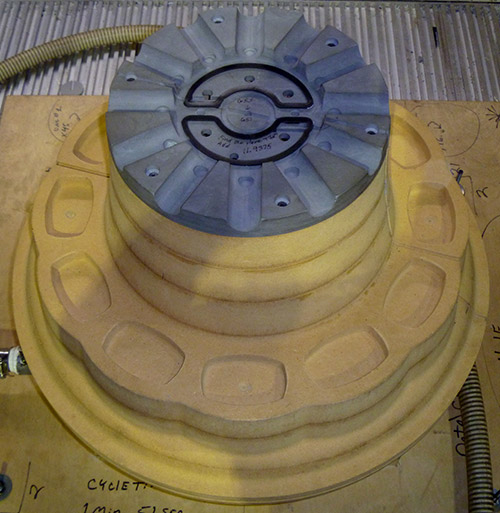

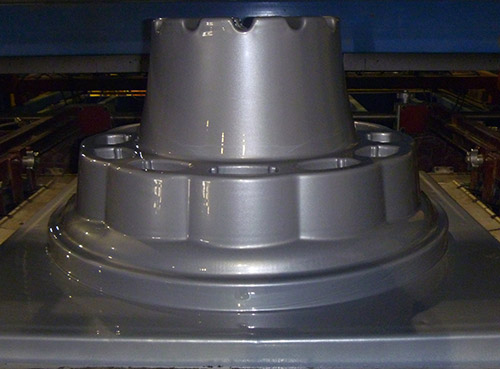

2. Mold & Tooling

Custom Mold Fabrication

Choose from aluminum (fast turnaround), phenolic (cost-effective for medium runs), or steel (durable for high volumes). Each mold is precision-machined to your part’s exact geometry.

Tool Lifespan & Maintenance

Expect 2,000–5,000 cycles per aluminum mold and 10,000+ for steel. We maintain and recondition tools in‑house to extend life and ensure consistent results.

Expect 2,000–5,000 cycles per aluminum mold and 10,000+ for steel. Our in‑house tool shop handles maintenance and reconditioning to extend life and ensure consistent results.

Advanced Venting & Vacuum Porting

Strategic placement of vacuum ports and vent channels guarantees uniform material stretch and minimizes thinning—critical for deep draws and complex contours.

3. Thermoforming

Thin‑Gauge vs. Heavy‑Gauge Operations

- Thin‑Gauge (<0.125″): Ideal for packaging, point‑of‑purchase displays, and protective covers. Cycle times under 30 seconds.

- Heavy‑Gauge (0.125″–0.500″): Used for durable housings, machine guards, and structural panels. Deep draws up to 36″ in a single operation.

Vacuum & Pressure Assist

- Vacuum Only: For simple shapes and moderate draws.

- Vacuum + Plug Assist: A plug presses the sheet into the mold before vacuum kicks in—essential for complex geometries, undercuts, and deeper draws.

Real‑Time Process Control

We use PLC‑driven presses to monitor temperature, vacuum level, and cycle time, ensuring consistent wall thickness and repeatable part quality across every run.

Our PLC‑driven presses monitor temperature, vacuum level, and cycle time, ensuring consistent wall thickness and repeatable part quality across every run.

4. Trimming & Assembly

Precision CNC Routing

5‑axis routers trim parts to ±0.010″ tolerances. Automated nesting maximizes yield and reduces scrap.

Value‑Add Secondary Operations

- Mechanical Assembly: Riveting, fastening, and insert installation.

- Foam & Rubber Insert: Bonded in place for cushioning or sealing.

- Chemical Welding & Solvent Bonding: Seamless joints for enclosures and tanks.

Clean & Package

Parts receive ultrasonic cleaning when needed, then are bagged, labeled, and kitted per your specifications—ready for immediate assembly or shipment.

5. Final QA & Shipping

In‑Line & Final Inspections

Gauge checks, visual audits, and full-dimensional reports ensure every part meets or exceeds spec. All inspections follow AS9100 protocols.

Traceability & Documentation

Batch numbers, material lot tracking, and inspection records are delivered with each shipment for full traceability.

Packaging & Logistics

Choose custom crating, stretch-wrapping, or skids. We coordinate with major carriers and offer JIT delivery to minimize your inventory footprint.

Materials & Cost Scale

MaterialThicknessKey PropertiesTypical UsesRelative Cost

HDPE | 0.030″–0.500″ | Chemical‑resistant, food-safe | Food service trays, packaging | $$

Kydex® | 0.020″–0.190″ | Flame‑retardant, rigid | Aerospace interiors, panels | $$$

Boltaron® | 0.030″–0.250″ | UV‑stable, abrasion‑resistant | Outdoor equipment, signage | $$$$

Relative cost: $ = low, $$$$ = premium.

| Material | Thickness | Key Properties | Typical Uses | Relative Cost |

|---|---|---|---|---|

| ABS | 0.020″–0.250″ | Impact‑resistant, paintable | Medical enclosures, consumer goods | $$ |

| HDPE | 0.030″–0.500″ | Chemical‑resistant, food-safe | Food service trays, packaging | $$ |

| Kydex® | 0.020″–0.190″ | Flame‑retardant, rigid | Aerospace interiors, panels | $$$ |

| Boltaron® | 0.030″–0.250″ | UV‑stable, abrasion‑resistant | Outdoor equipment, signage | $$$$ |

| Relative cost: $ = low, $$$$ = premium. | ||||

Industry Case Studies

Aerospace Enclosure

Client:

Global avionics OEM needed a lightweight housing for a new flight-control module.

Challenge:

Tight tolerances (±0.005″) on a part measuring 24″×18″×6″ with complex undercuts.

Solution:

Heavy‑gauge ABS vacuum thermoforming plastic with plug assist, followed by precision CNC trimming and solvent bonding for a seamless seal.

Result:

Achieved cycle time reduction of 20%, met tolerance goals, and eliminated secondary machining—saving $50K annually in labor.

Medical Device Panel

Client:

Leading manufacturer of dialysis equipment required a biocompatible access panel.

Challenge:

Complex geometry with integrated mounting bosses, chemical resistance to cleaning agents, and ISO 10993 compliance.

Solution:

Formed Kydex® sheet in a custom mold, then bonded foam gasket and stainless-steel inserts. Full ultrasonic cleaning to medical standards.

Result:

Panels passed biocompatibility testing, zero field failures in first year, and streamlined assembly by 30%.

Agricultural Canopy Cover

Client:

Farm equipment manufacturer designing protective canopies for open‑cab tractors.

Challenge:

Deep draw (36″) on HDPE with long-term UV exposure and high impact resistance.

Solution:

5‑year outdoor warranty granted, material costs reduced by 15%, and assembly time cut in half.

Result:

Achieved cycle time reduction of 20%, met tolerance goals, and eliminated secondary machining—saving $50K annually in labor.

Frequently Asked Questions

Up to 0.500″ in heavy-gauge runs.

Draw depths reach 36″; deeper options available on request.

Standard: 2–3 weeks. Expedited: 7–10 days with rush service.

Yes—color matched paint, silk-screen printing, and post-forming coatings.

Small runs (50–100 pcs) are common; MOQ varies by geometry and material.

Yes—quality systems audited annually to ensure compliance.

Absolutely—a detailed report helps you avoid costly redesigns.

We provide mechanical fastening, foam inserts, solvent bonding, and complete kitting.

ABS, HDPE, Kydex®, Boltaron®, vinyl, PETG, and more.

Click “Request a Quote,” email quotes@rfpllc.com,