Precision Thermoformed Components for the Aerospace Industry

At Reliable Formed Plastics, we have a proven track record of manufacturing high-quality, durable components for Tier 1 Aerospace Suppliers and OEMs. Our expertise in thermoforming top-grade plastic resins offers a cost-effective, lightweight alternative to traditionally metallic aerospace parts — without compromising strength, durability, or performance.

By utilizing advanced thermoplastic materials, we can produce critical aerospace components that meet low-tolerance industry standards while significantly reducing cost and weight. Our precision-formed parts include, but are not limited to:

- Interior panels and covers

- Instrument bezels and housings

- Protective cases and enclosures

- Transparencies, such as instrument windows and exterior lenses

We specialize in processing a wide range of high-performance, aerospace-grade materials, including:

- ULTEM® (PEI)

- Boltaron®

- Kydex®

- Polycarbonate (Lexan®) / FR Polycarbonate

- Nylon

- Acrylic

- Composite and fiber-reinforced resins

Our facility operates under a rigorous quality management system, holding both AS9100 Rev. D and ISO 9001:2015 certifications, ensuring that every part we manufacture meets the highest standards of precision, safety, and performance. We also offer assembly and sub-assembly services, allowing us to deliver ready-to-use components for streamlined production and integration.

At Reliable Formed Plastics, we are committed to supporting the aerospace industry with superior thermoformed solutions — delivering lightweight, high-strength components that drive efficiency and innovation in aircraft design and manufacturing

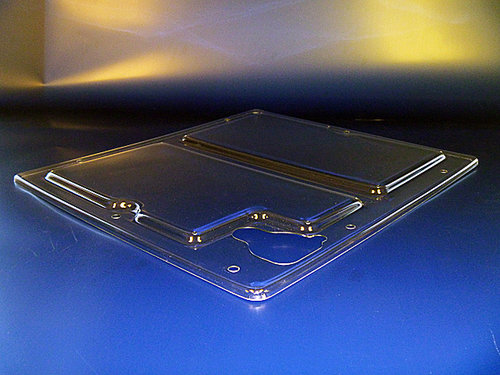

LEXAN WINDOW

Pictured to the right is a Lexan window for an instrument panel on a helicopter. Custom molds and trim fixtures were also planned and fabricated for our aerospace customer. The part was created using SolidWorks CAD software and manufactured with the help of Mastercam CAM software. A first article inspection (FAI) was produced from 9034 Lexan (polycarbonate) and sent to the client for approval. Once approved, vacuum thermoforming followed by 5-axis CNC routing were employed to create the instrument panel window.

ULTEM EXHAUST PORT

COMPOSITE FABRICATION

Reliable Formed Plastics also has the ability to form fiber woven/impregnated materials. These composite materials often serve as excellent Flame, Smoke, and Toxicity deterrents which are highly valued in many aerospace applications. The result in forming such materials is a very high grade, highly durable, yet extremely light weight product. Pictured below Glass ULTEM and Carbon Fiber covers.